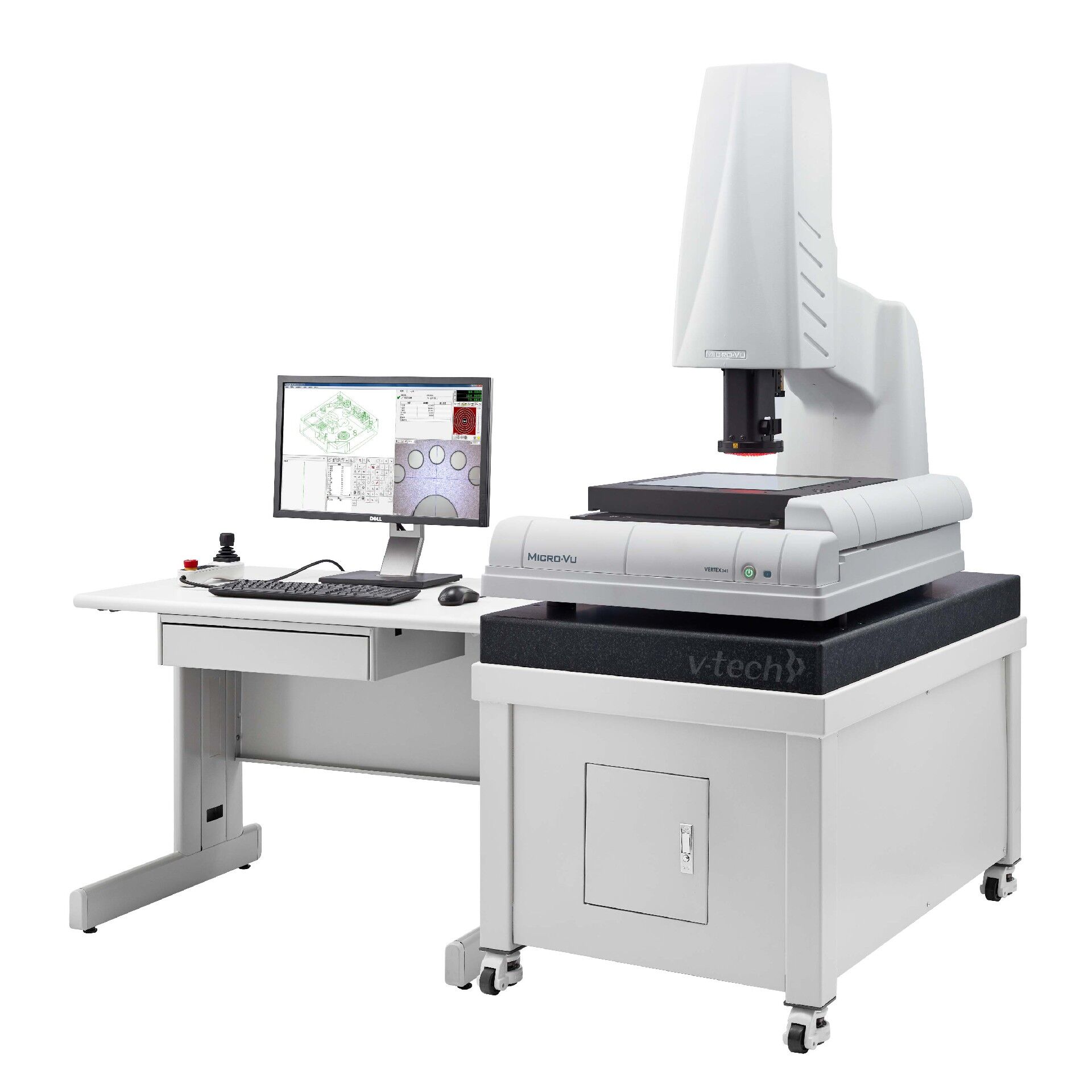

MICRO-VU VERTEX 261/341/342 Series -Small Range

Measuring Range (XY): 250×160 mm-315×315 mm

Measuring Height (Z): 160-250 mm

Vertex Automated Vision Measuring Machine is widely used in industries as Aerospace, Military, Connector, Electronics and O-ring etc.

Touch Probe and Laser can be added on the vision measuring machine to construct multisensory measuring system and finish the measurement of some special dimensions.

Overview

The Vertex Measuring System implements new technologies to provide speed and accuracy on a reliable and affordable measuring machine.

The system includes InSpec Metrology Software, a programmable optical zoom, 3x digital zoom, non-linear stage compensation, non-linear optics compensation, advanced LED lighting, and active temperature monitoring.

InSpec Metrology Software provides point-click simplicity, proprietary edge detection, advanced lighting control and calibration, multi-sensor integration, automated calibrations, and a clear display of measurement data and tolerances.

Included services :

Installation of Micro-vu Machine

Training of Micro-vu Machine

Calibration of Micro-vu Machine

Maintenance of Micro-vu Machine

Repair of Micro-vu Machine

Specification

| Model | Measuring Range (mm) | XY Accuracy (μm) | Z Accuracy (μm) | Resolution | Capacity | Machine Dimensions (mm) |

| Vertex 261 | 250x160x160 | 2.0+L/250 | 2.0+L/200 | 0.1 μm | 10 kg | 755x1130x1075 |

| Vertex 341 | 315x315x160 | 2.6+L/175 | 3.0+L/150 | 0.1 μm | 20 kg | 900x1410x1065 |

| Vertex 342 | 315x315x250 | 2.6+L/175 | 3.0+L/100 | 0.1 μm | 20 kg | 900x1410x1245 |

Optional fittings

Application

Measurement Production Line Upgrade | Robot Automatic Loading and Unloading

Knotless Screen Mapping Application | Micro-Vu High Precision Vision Measuring Machine

Cell Measurement Application | Micro-Vu high-precision vision measuring machine

Download