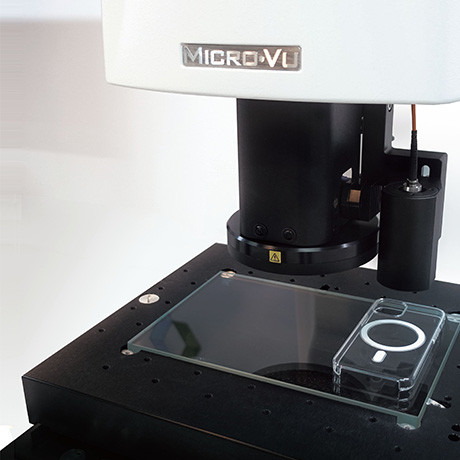

Micro-Vu Vision Measurement Systems

Micro-Vu was established in California, USA in 1959. Over the past 60 years, Micro-Vu’s vision measuring machines have been widely commended in the international market, and it is the highest market share of vision measuring machine in the world.

Excellent performance, accuracy, speed. Price advantage compared with products at the same level and best cost-effective among similar products due to standardized production.

40,000 purchasing record around the whole world.

Measuring Range (XY): 250x160 mm-315x315 mm Measuring Height (Z): 160-250 mm Vertex Automated Vision Measuring Machine is widely used in industries as Aerospace, Military, Connector, Electronics and O-ring etc. Touch Probe and Laser can be added on the vision measuring machine to construct multisensory measuring system and finish the measurement of some special dimensions.

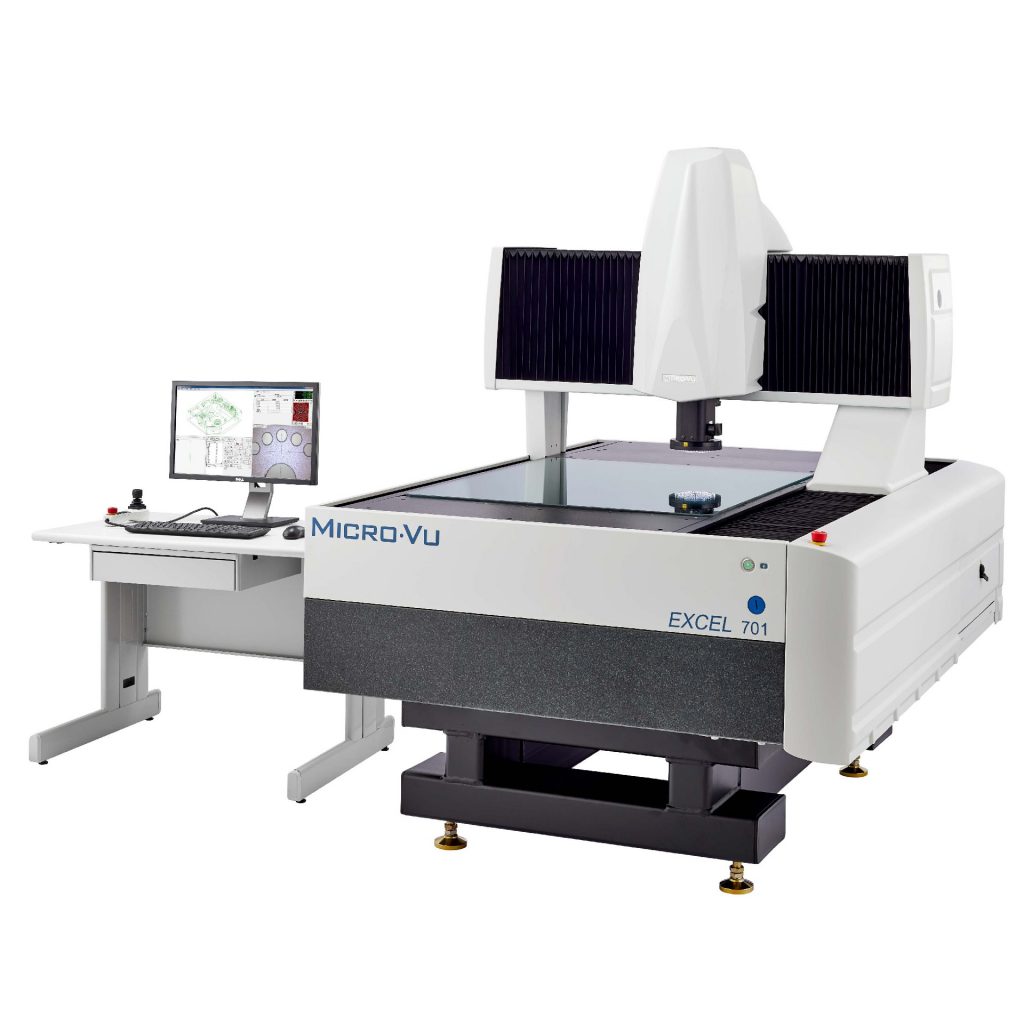

Measuring Range (XY): 420x520 mm-660x700 mm Measuring Height (Z): 160-400 mm Excel 500/700 Automated Vision Measuring Machine, is widely used in industries as PCB, Mobile Phone, O-Ring, Gasket, Automobile etc. Touch Probe, Laser and Rotary can be added on the vision measuring machine to construct multisensory measuring system and finish the measurement of some special dimensions.

Micro-vu Excel 901/902/904/1301/1302/1304/1701/1702/1704/2500

Measuring Range (XY): 750x900 mm-1600x2560 mm

Measuring Height (Z): 160-400 mm

Excel 900/1300/1700/2500 Automated Vision Measuring Machine, is widely used in industries as Aerospace, PCB, Machining, Sheet Metal etc. Can add Touch Probe, Laser and Rotary on the vision measuring machine to construct multisensory measuring system.

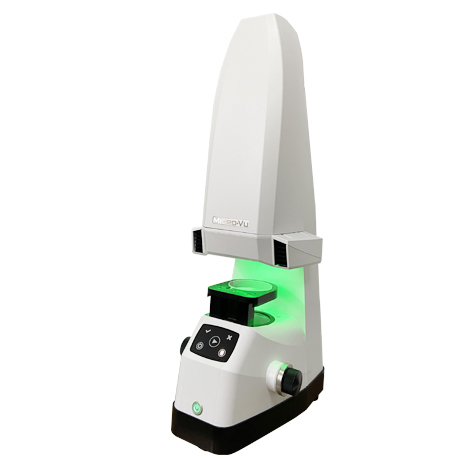

Field of View (Low Mag)/Depth of Field: 69.3x49.6 mm/30 mm Field of View (High Mag)/Depth of Field: 17.3x12.4 mm/3 mm With one simple click, the system provides all the measurements including distance, radii, diameter, angle, straightness, roundness, giving intuitive OK/NG feedback directly on front touch panel, permitting accurate and objective quality control on production pieces.

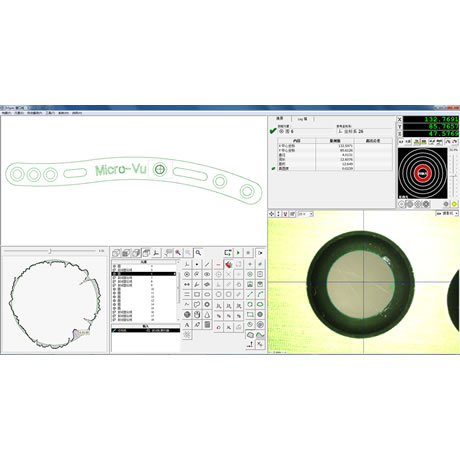

High level metrology software in the industry. All models of Vertex and Excel are installed with InSpec software.

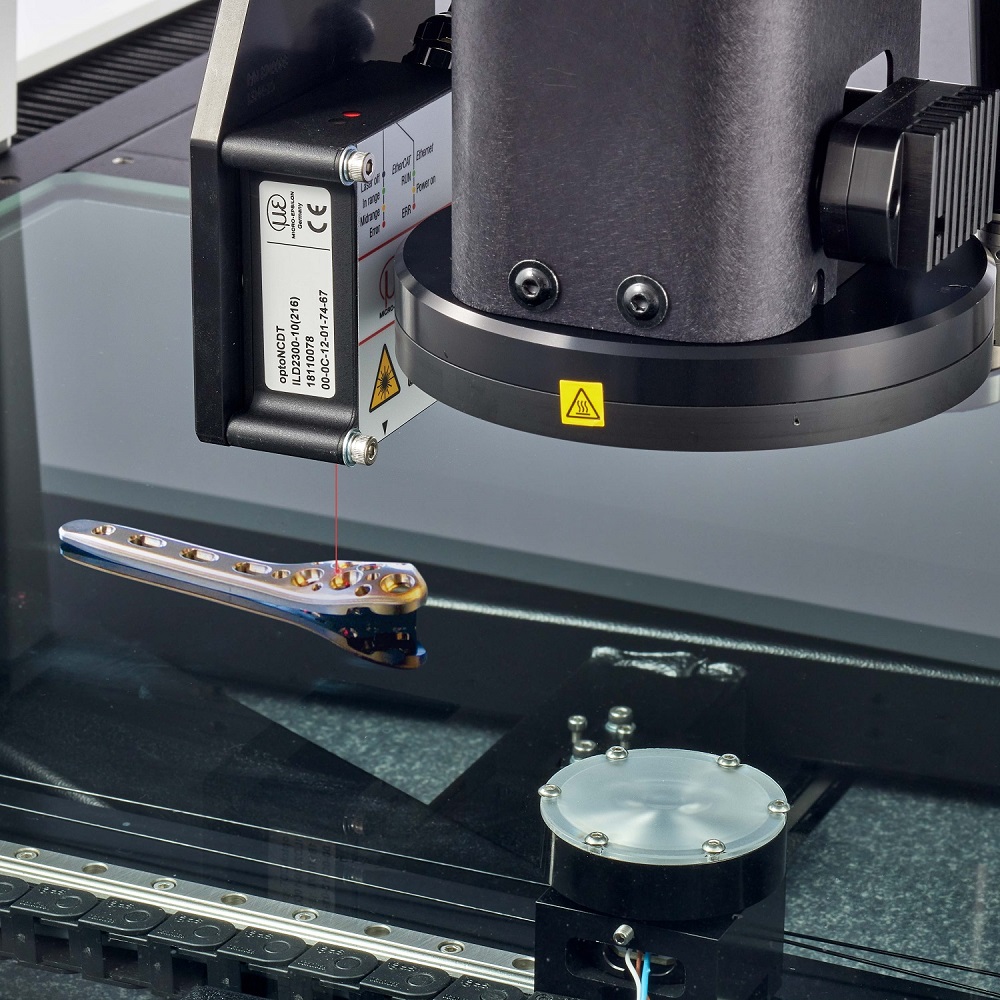

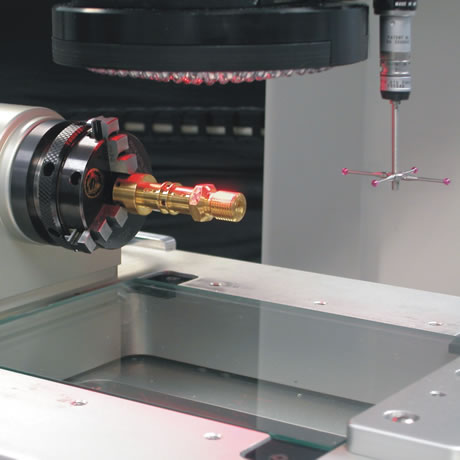

Measure Dimensions of Grooves or Side Holes. Touch Probe can be optionally added to Micro-Vu vision measuring machine to construct a multi-sensor measurement system to complete measurement of some special sizes.

RSD-60 rotary indexer is an angle positioning device, which is closely integrated with the measurement software. It can rotate the measuring piece accurately, then the camera can observe multiple surfaces and measure the shaft in a rotating manner (W axis). No additional setting is required, reducing operation time.

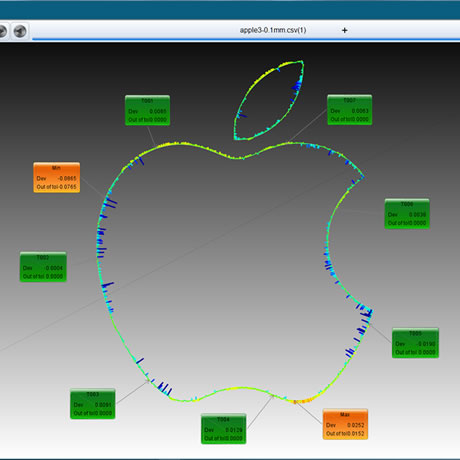

With more than 60 years of experience in the software development, FormFit 2D Best Fit Software developed by Micro-Vu is designed to be easy to use, providing functions as Fitting, Editing, Analyzing and Reporting etc. It connects with InSpec Metrology Software, compares the data automatically after measurement and exports report. Functions: 1. Whole/Partial Deviation Analysis 2. GD&T Analysis as True Position etc. 3. Profile Calculation 4. Connect with InSpec to Export Inspection Report

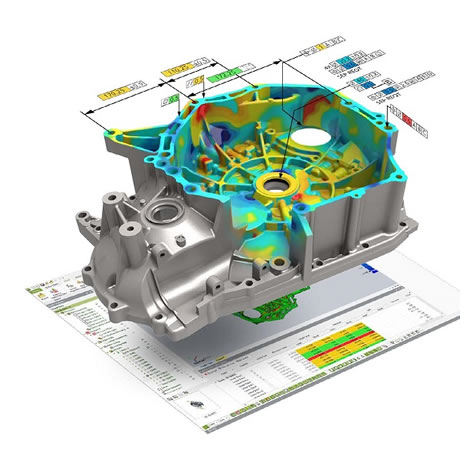

Geomagic Control is a professional metrology software, which can integrate with Micro-Vu high precision vision measuring machine in order to perform editing, CAD comparison and GD&T on the inspecting piece. Application fields: 1. Data scanning, CAD alignment and comparison. 2. 3D dimension deviation analysis, geomatic tolerance calculation. 3. Interactive 3D model report. 4. Process automation from alignment to reporting.

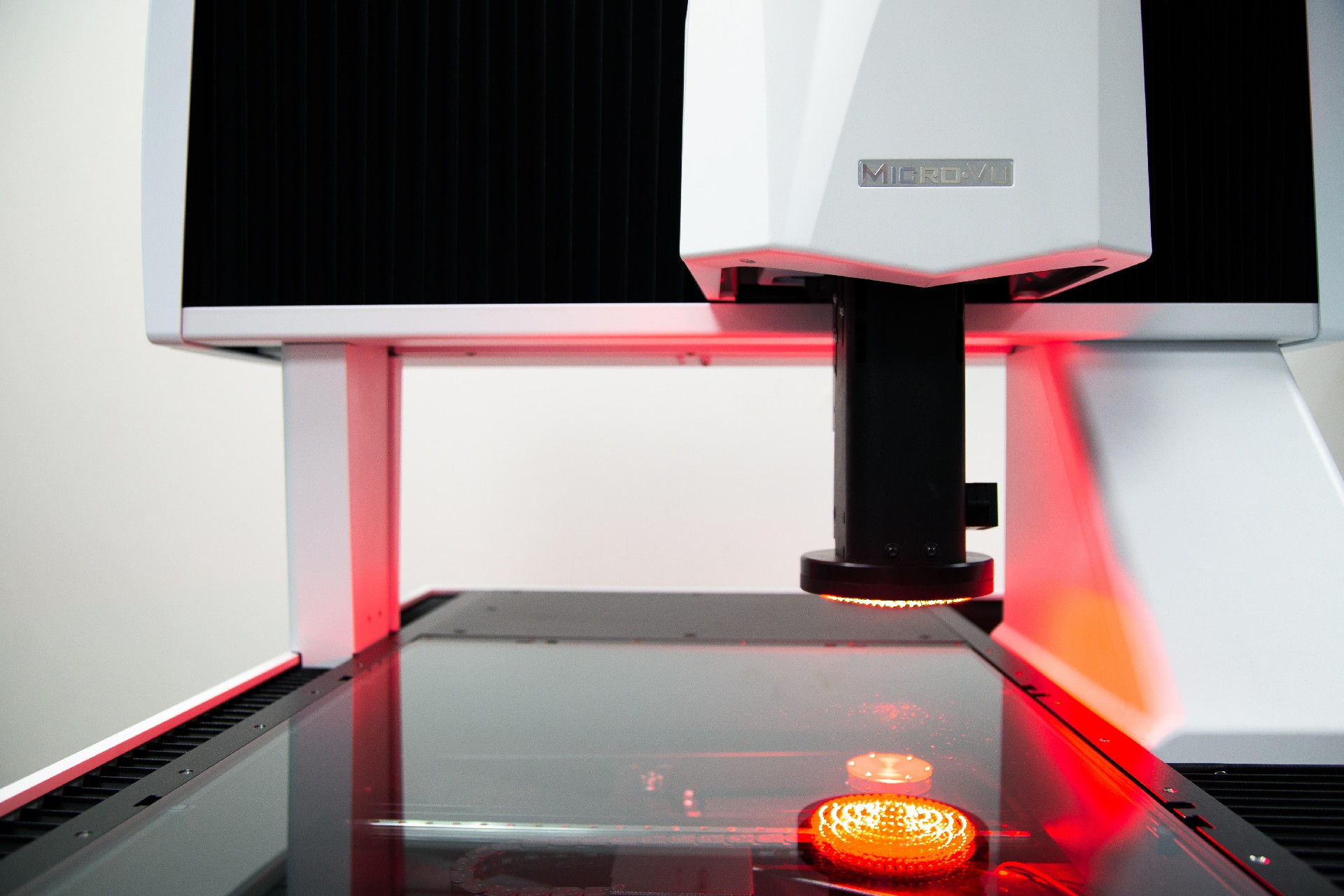

The surface light is produced with a ring of LEDs around the lens. Directional Light from 27° to 75°. Macro Ring Light: 5 rings, 8 sectors, 40 segments. Long and short working distances

One robot arm can be equipped with multiple sets of Micro-Vu vision measuring machines, to realize automatic loading and unloading operation. The robot arm realizes the automatic operation of loading and unloading of the measuring machine through TCP/IP communication. One robot arm can be equipped with multiple sets of Micro-Vu vision measuring machines.

Automatic loading and unloading. Automatic loading and unloading to the measuring machine. Automatic measurement. The system calls the measurement program and completes the measurement automatically. The system judges the measuring piece as NG or OK according to the measuring result, and places the piece in the designated position.

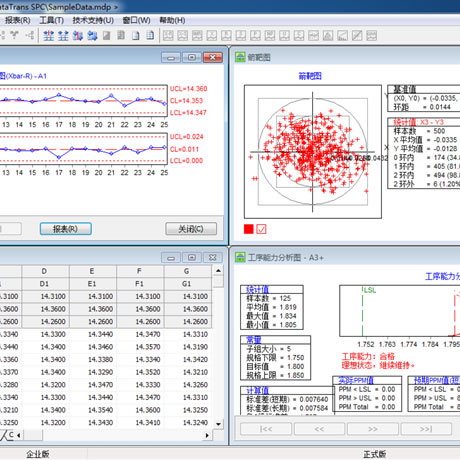

Statistical Processing Control Software with Self-definition Report Output. It is operating with Microsoft Excel.

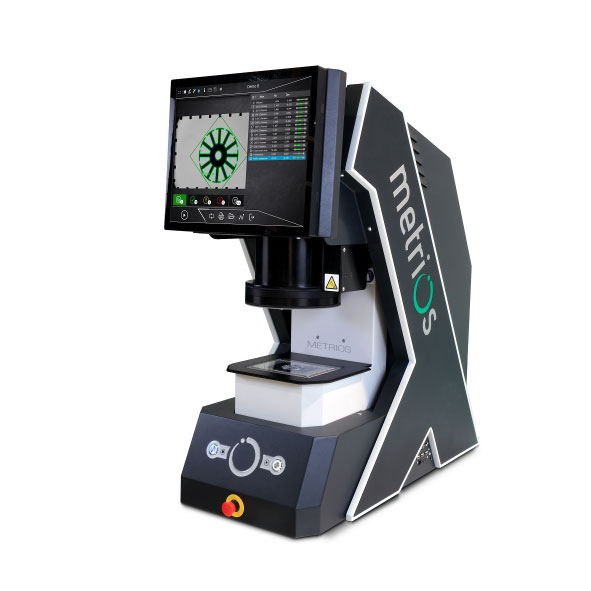

VICIVISION, Metrios Optical Measuring Machines

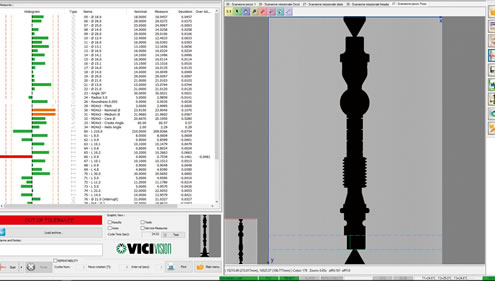

VICIVISION manufactures MTL optional, non-contact shaft measuring machines and quality control system for the improvement of efficiency in production. VICIVISION is one of the key players in the world of turned measuring technology, serving a wide range of end users.

MTP is an optical measuring machine capable of controlling in a single scan multiple pieces placed on a stage.

Metrios optical measuring machine performs accurate and objective quality tests directly in production.

Tiếng Việt

Tiếng Việt