Overview

M1c is ideal for measuring minute turned parts. Designed to increase production, reduce costs and achieve greater efficiency on smaller batches.

Measuring Range: 160×60 mm.

M1 can measure turned parts from simple fittings to small shafts. Even faster, this series reduces measuring times and sets a new bar in its sector.

Measuring Range: 300×60 mm.

M2 and M3 measure small components as easily as large shafts, capturing the finest details such as ridges and radii.

Measuring Range: for small turned parts or large shafts up to 900×140 mm.

Load capacity can be increased, which allows elements up to 240 mm in diameter to positioned.

Video Product

Software

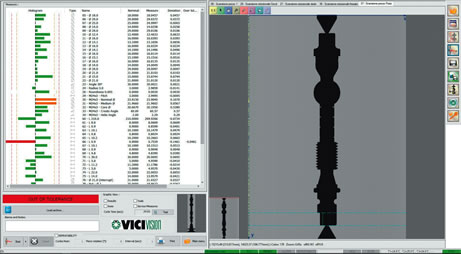

Immediate Inspection

Immediate Inspection

Reduction in machine downtime thanks to immediate inspection without the need to leave the workstation.

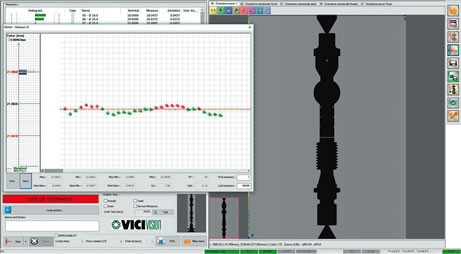

Significant reduction in rejects, implementing the preventive actions indicated by the measurement trend graphs.

Off-line Programming

Off-line Programming

Create measurement programs from the comfort of your desk while the machine is used by operators.

Live Measurements

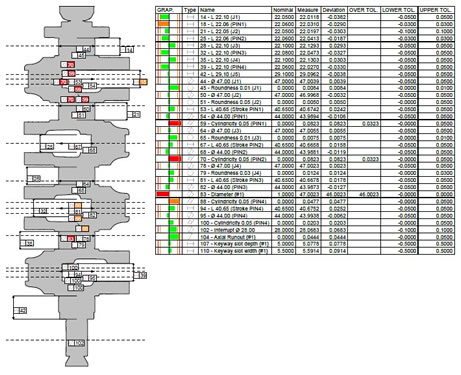

Once the live image of the component has been captured, the software collects all the static measurement data and instantly issues a report for each component measured.

VICIVISION Tool-loop

It is possible to set the interface between MTL and the workstation to automatically correct tool parameters.

This function eliminates human error and speeds up tool parameter settings. Each part produced is ready to be delivered.

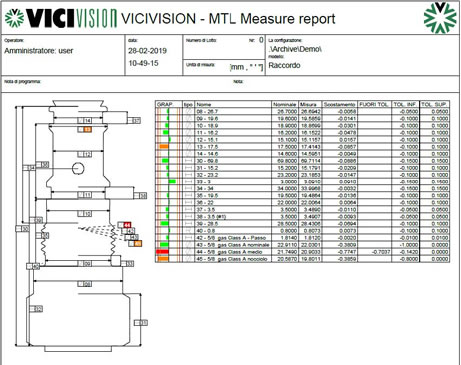

Measurements Report

The software allows the operator to print or export complete and custom pdf measurement reports. Results of measurements on histograms for immediate consultation.

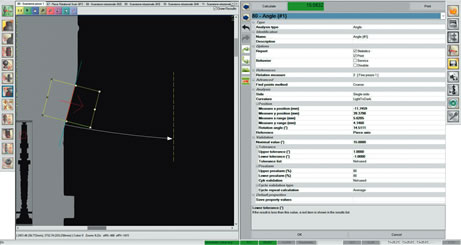

Cutting-edge Software

The brand new MTL 8.10 version is designed to improve the control phase and further extend the number of possible measurements. It includes specific tools for static and dynamic measurements, and dedicated tools for threads nuts, camshafts, turbines, etc.

Features

Working Area

Working Area

The live image of the part displayed by the software, combined with the LED illuminated extensive working area, gives a clear vision of the conditions of the component being measured.

The retractable sensors enabled during loading and unloading provide reinforcement, with additional one of a kind protective bumper.

Ergonomic Design

The ergonomic piece clamping lever has a considerably wide grip, which is suitable both for left and right-handed operators and prevents obstruction of the view when clamping or unclamping the part.

Application

Measurement Production Line Upgrade | Robot Automatic Loading and Unloading

With the continuous integration of informatization and industrialization, and the continuous development of the intelligent manufacturing industry, the intelligent industry represented by robot arm is booming. The emergence of industrial robot arms solved the difficult recruitment problems caused by the harsh working environment and high labor intensity.Using a robot arm instead of an operator can

MTL Application | Interview with Italy Sarbo Minuterie Metalliche

Sarbo S.p.A. is a leading company in the specialized production of bar-turned small metal parts. The company is undergoing a crucial and advantageous period with a generational changeover from partners Luciano Zago and Giuseppe Sartor, to their children, Paolo Zago and Roberta Sartor. The new generation has enthusiastically welcomed the handing down of know-how and

Crankshaft Measurement | In Less Than A Minute

When it comes to quality control of such complex parts, measuring crankshafts can be a cumber some and time-consuming process, possibly requiring an environmentally controlled room. VICIVISION has developed a specific software tool dedicated to crankshaft measurements, able to provide dimensional control results of the highest accuracy. VICIVISION measurement systems offer a solution for specific

VICIVISION | Fittings and Turned Threads: How to Measure Them In A Few Seconds

Measuring Fittings, Turned Threads and Screws It is often difficult for manufacturers to get accurate and objective results when measuring turned threads, typical features on fittings and shafts, and rolled threads.By working closely alongside our clients and listening to their needs, we have developed a specific software for measuring fittings. In addition to standard

Download

Tiếng Việt

Tiếng Việt