When it comes to quality control of such complex parts, measuring crankshafts can be a cumber some and time-consuming process, possibly requiring an environmentally controlled room.

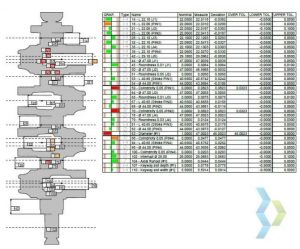

crankshaft measurements, able to provide dimensional control results

of the highest accuracy. VICIVISION measurement systems offer a solution for specific dimensions of the eccentric pin:

Crankshaft Features to Measure:

· Diameter

· Roundness

· Cylindricity

· Run-out

· Timings

· Dynamic parallelism

· Radii

The software prov ides export to a DXF file of the pin radii before the rolling process, al lowing the operator to save it along with the part serial number.

After rolling the previously saved profile can be imported and compared with the actual profile in order to check the penetration parameters.

VICIVISION’ s optical measurement systems automatically collect data and produce a measurement report in under a minute.

Dimensional control directly on the shop floor.

Each part produced by the CNC lathe can be easily measured by operators within the production environment.

Greater productivity also on smaller batches.

Batch changing is fast and efficient.

One measuring system for multiple CNC lathes.

One measuring system for multiple CNC lathes.

High resolution.

Detailed images capture even minute features.

No more compromises.

Given the wide scope of measurement ranges offered, this machine range is designed to adapt to current and future manufacturing demands.

Tested reliability.

Specific expertise and carefully selected components have created a highly efficient range of solutions.

Heavy Duty.

The load capacity of the largest machines has increased by up to 60 kg.

Techno Measuring Range:

Diameter: 40 mm-180 mm

Length: 300 mm-1250 mm

| Model | Measuring Range (mm) |

Max. Loadable Sizes (mm) |

| M304 | 300×40 | 315×120 |

| M306 | 300×60 | 315×120 |

| M309 | 300×90 | 315×120 |

| M314 | 300×140 | 300×240 |

| M318 | 300×180 | 300×240 |

| M604 | 600×40 | 625×120 |

| M606 | 600×60 | 625×120 |

| M609 | 600×90 | 625×120 |

| M614 | 600×140 | 625×240 |

| M618 | 600×180 | 625×240 |

| M906 | 900×60 | 925×120 |

| M909 | 900×90 | 925×120 |

| M914 | 900×140 | 925×240 |

| M918 | 900×180 | 925×240 |

| M1209 | 1250×90 | 1300×120 |

| M1214 | 1250×140 | 1300×240 |

| M1218 | 1250×180 | 1300×240 |

Tiếng Việt

Tiếng Việt