Overview

High resolution. Detailed images capture even minute features.

A single measurement system can operate next to multiple machining centers, involving more than one operator.

This measuring machine range is designed to adapt to current and future manufacturing demands.

Video Product

Software

Immediate Inspection

Reduction in machine downtime thanks to immediate inspection without the need to leave the workstation.

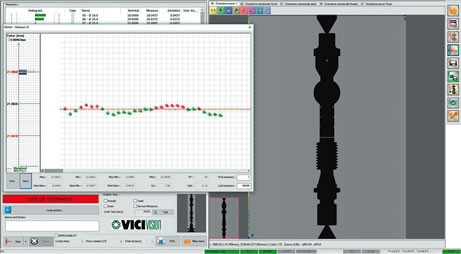

Significant reduction in rejects, implementing the preventive actions indicated by the measurement trend graphs.

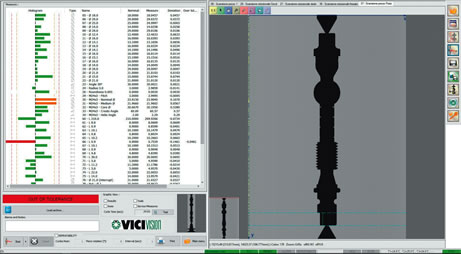

Live Measurements

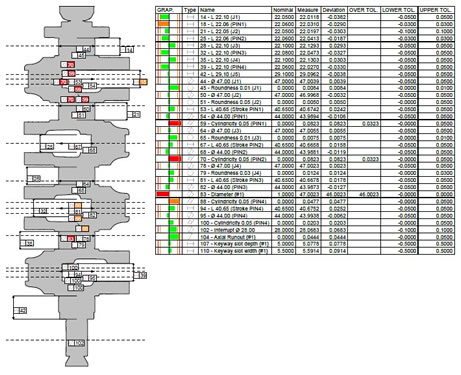

Once the live image of the component has been captured, the software collects all the static measurement data and instantly issues a report for each component measured.

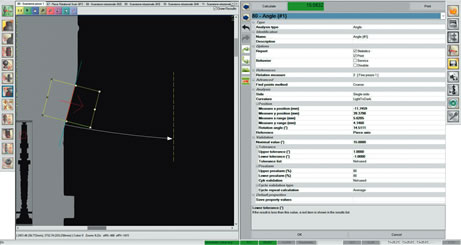

Off-line Programming

Create measurement programs from the comfort of your desk while the machine is used by operators.

Vivivision Tool-loop

It is possible to set the interface between MTL and the workstation to automatically correct tool parameters.

This function eliminates human error and speeds up tool parameter settings. Each part produced is ready to be delivered.

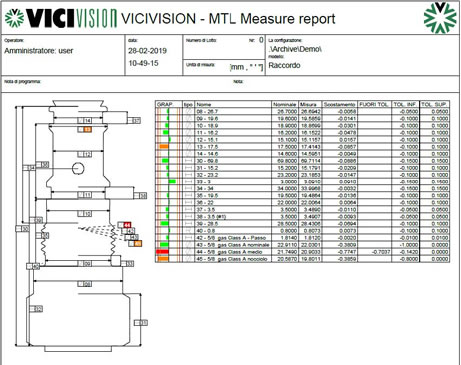

Measurements Report

The software allows the operator to print or export complete and custom pdf measurement reports. Results of measurements on histograms for immediate consultation.

Cutting-edge Software

The brand new MTL 8.10 version is designed to improve the control phase and further extend the number of possible measurements. It includes specific tools for static and dynamic measurements, and dedicated tools for threads nuts, camshafts, turbines, etc.

Features

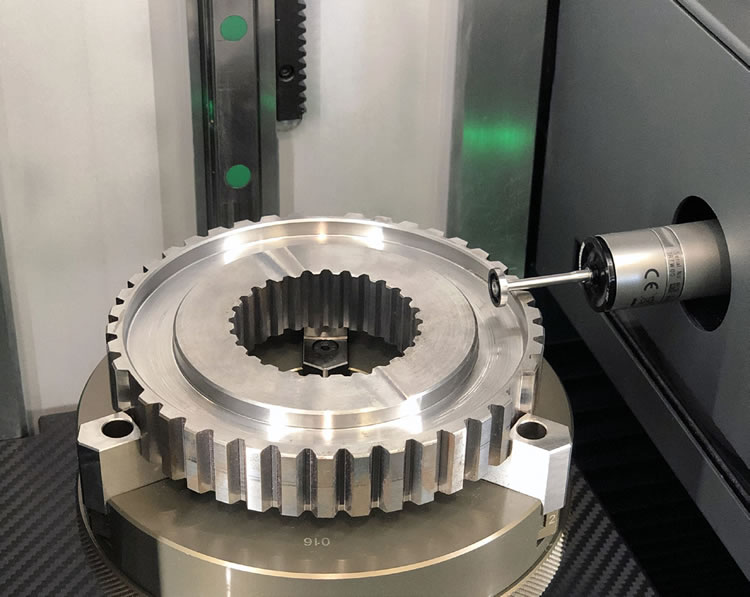

The VICIVISION measuring machines in the Techno series, equipped with the new touch probe system, offer greater possibilities for measuring shafts and turned parts, directly on the shop floor.

The Techno range runs a higher number of measurements, without having to go to the metrology lab or having to use additional external instruments.

Possibility to integrate robotics. Automatic loading and unloading means 100% inspection of production without additional costs.

Barcode reader. Move from one piece to another by scanning the barcode.

Application

Medical device application case | MTL measuring Ompi vial

Stevanato Group boasts more than 70 years of experience in the production of glass packaging. Ompi is a medical system division of Stevanaoto Group. It has branch companies in Italy, Slovakia, Mexico, China, Brazil and other countries. It provides a wide range of glass inner packaging materials, including the glass vials, a traditional product.

MTL Application | Interview with Italy Sarbo Minuterie Metalliche

Sarbo S.p.A. is a leading company in the specialized production of bar-turned small metal parts. The company is undergoing a crucial and advantageous period with a generational changeover from partners Luciano Zago and Giuseppe Sartor, to their children, Paolo Zago and Roberta Sartor. The new generation has enthusiastically welcomed the handing down of know-how and

Crankshaft Measurement | In Less Than A Minute

When it comes to quality control of such complex parts, measuring crankshafts can be a cumber some and time-consuming process, possibly requiring an environmentally controlled room. VICIVISION has developed a specific software tool dedicated to crankshaft measurements, able to provide dimensional control results of the highest accuracy. VICIVISION measurement systems offer a solution for specific

VICIVISION | Fittings and Turned Threads: How to Measure Them In A Few Seconds

Measuring Fittings, Turned Threads and Screws It is often difficult for manufacturers to get accurate and objective results when measuring turned threads, typical features on fittings and shafts, and rolled threads.By working closely alongside our clients and listening to their needs, we have developed a specific software for measuring fittings. In addition to standard

Download

Tiếng Việt

Tiếng Việt