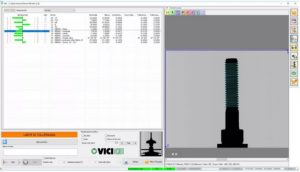

In addition to standard measurements, such as diameter, length, angle, radius and chamfers, specific dimensions for threaded parts can be obtained.

A single software tool can automatically measure fittings and turned threads, as well as screws and bolts, in a matter of seconds.

Measurements List

●Pitch

●Nominal diameter

●Mean diameter

●Core diameter

●Roll dimension

●Crest angle

●Crest cut-off

●Pitch

●Mean diameter

●Core diameter

●Crest cut-off

●Distance of known diameter (gauge length)

●Thread taper (thread angle)

●Root taper angle

●Diameter at a known position

In addition to the previously listed static measurements, a series of dynamic measurements can also be taken on threads:

●Roundness

●Coaxiality

●Run-out

●Cylindricity

As well as standard thread measurements, such as pitch, nominal diameter, mean diameter and core diameter, we have developed functional measurements for the production of screws and bolts with rolled threads:

●Helix angle (to see if the rolls “slide”)

●Single position of the NG (not good) diameter – to check if a single crest or groove is not correctly formed.

●LG dimension

In addition to roundness, coaxiality, run-out and cylindricity, we have developed a specific software for trilobe screws.

This eliminates the repeated search for nominal values and tolerances and therefore speeds up programming.

Furthermore, the tables are open, which means that the operator can duplicate them and manually insert new dimensions and tolerances where necessary, to add or remove machining allowance.

VICIVISION MTL Optical Measuring Machine-Techno, X, M series

Tiếng Việt

Tiếng Việt