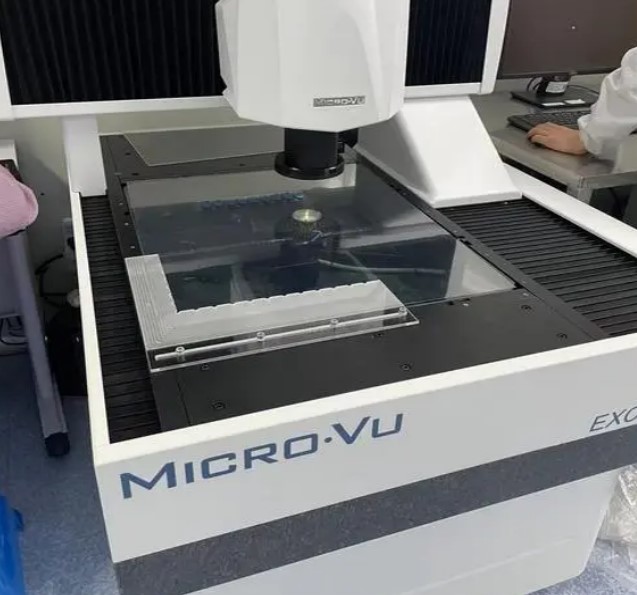

Why is it necessary to calibrate the Micro-vu measuring machine? When is calibration needed?

As we all know, there is no device or machine that can last forever without changing or otherwise aging, and so is the Micro-vu machine.

To ensure the most efficient operation of the Micro-vu measuring machine, and to avoid erroneous measurement results affecting the product, Vertex recommends that customers carry out an annual calibration ( Once a year).

Calibration is a very important activity in ensuring that instrument deviation is minimized. There are even some high-quality devices that are still skewed and unable to provide accurate readings.

Calibration is concerned with determining the level of accuracy, determining the error of a measuring instrument. This is done through the direct comparison of a measuring instrument with known standards of measurement in order to provide a formula to help the user determine the exact value of quantities when measured by that instrument.

Vertex is committed to all calibration content in accordance with Micro-vu’s procedures. After the calibration process is over, our engineering team will use the 600 standard ruler that has been tested by the metrology institute to evaluate the calibration results. At the same time, we will provide a full calibration report to the customer, stick the calibration term on the device and guarantee the calibration results for 1 year.

Tiếng Việt

Tiếng Việt

Related Posts

Renting service of 2D/3D Micro-vu measuring machine

Repair (Replace parts / Upgrade software) of Micro-vu measuring machine

Installation and Training service of 2D, 3D Micro-vu measuring machine

Maintenance service of 2D/3D Micro-vu Measuring Machine in Vertex

Calibration service of 2D/3D Micro-vu Measuring Machine in Vertex