Stevanato Group boasts more than 70 years of experience in the production of glass packaging. Ompi is a medical system division of Stevanaoto Group. It has branch companies in Italy, Slovakia, Mexico, China, Brazil and other countries. It provides a wide range of glass inner packaging materials, including the glass vials, a traditional product.

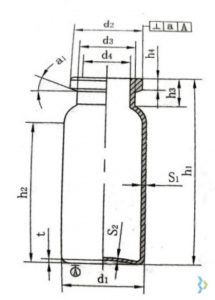

Ompi vial is glass container for medicine. Due to the optimization of its bottom depression, it is available in different sizes and capacities, which can hold liquid and freeze-dried drugs.

The complexity of drugs means that packaging material suppliers must develop new methods to ensure the stability between the drug and the container and ensure perfect drug management. The requirements for the appearance performance od the container have become one of the necessary conditions.

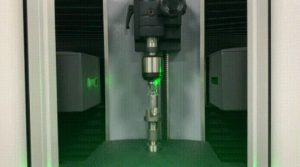

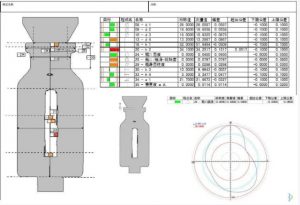

Ompi China chose VICIVISION MTL M1 optical measuring machine to strictly manage quality of dimensional changes of its vials.

Automatic cycle by pressing a button. Automatic data collection.

Easily reproduce the measurement position, lighting settings, measurement tools etc., and automatically recognize profile of the measuring piece.

1. Higher efficiency for small batch inspection and batch change. It can complete the customization of end customers from standard to specific application products, while greatly reducing the time to market.

2. Eliminate human error and ensure high appearance quality. Even in the face of most demanding drugs, it can provide a high level of quality, safety and technology.

3. Unlimited measurement items and quantity, reducing cost pressure.

Tiếng Việt

Tiếng Việt