Sliding Stage Series

Measuring Range: 265×200 mm/70×70 mm.

2 models: METRIOS CROSS, METRIOS HD CROSS.

METRIOS CROSS: Sliding stage along X and Y axis, wide working area and high resolution across the entire field of view.

METRIOS HD CROSS: Highest resolution of the range. Sliding stage along X and Y axis.

Overview

METRIOS is a state of the art, automatic and digital optical measuring machine designed for shopfloor inspection.

It performs accurate and objective quality tests directly in production, when parts are incoming or during final inspection prior to shipment, thus increasing productivity and reducing costs.

Objective and digital measurements during the process eliminate human error and reduce rejects.

Smart, automated, digitalized factories optimizing production processes.

1. Speed: Takes even complex measurements in a matter of seconds. Distances, radii, diameters, angles, straightness, roundness, as well as elements constructed on virtual lines.

2. Intuitive: A simple, intuitive click provides all the measurements required.

3. Versatility: Designed to measure anything from metal components to deformable materials.

4. Objectivity: Consistent results unconditioned by the operator.

5. Customized: In-house software development to meet the users’ requirements.

Specification

| Model | Field of View | Max. Piece Size on Z axis | Max. Weight Load |

| METRIOS CROSS | 265×200 mm | 80 mm | 5 kg |

| METRIOS HD CROSS | 70×70 mm | 80 mm | 3 kg |

Video Product

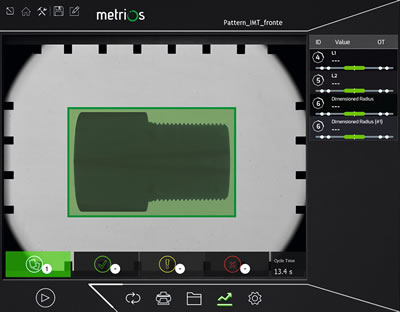

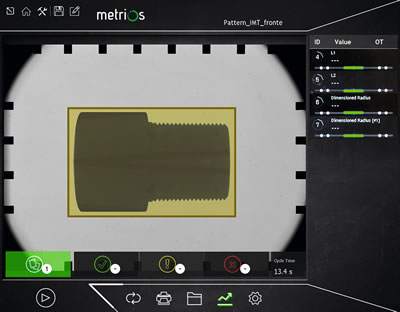

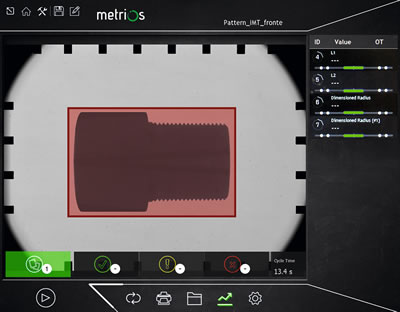

Software

Highly practical and intuitive, it does not require specialized operators.

The histogram display provides an immediate good/reject result.

The operator sees the live image of the part directly on the screen and has the same practical sensation as when using the profile projector.

The measurements highlighted by the histogram are indicated on the live image of the element. This function provides the operator with immediate control.

Data Collection:

METRIOS automatically collects data, eliminating the risk of human error, saving time and providing an analytical assessment of the production trend.

Automatic Measurement Trend

A graph shows the trend of each single measurement, providing the following information: average trend, maximum deviation, mean deviation, CP, CPK.

Instant Measurement Report

The software can print a complete and customizable report or export it in PDF format.

The histogram immediately shows if each single measurement is within tolerance and if there is any deviation from the nominal value.

Features

Automatic Measurement System:

1. Automatic position detection: Free hand rapid positioning, no need for accurate placement.

2. Limitless measurements for each piece: Complex parts with countless details: METRIOS acquires all the measurements in just a few seconds.

3. Multipiece measurements: METRIOS inspects multiple parts at the same time.

Optical Measurement Unit:

METRIOS acquires measurements with a non-contact optical system.

The system consists of a high-resolution sensor and three different lighting systems.

Telecentric Backlighting

For maximum accuracy and repeatability on profiles.

Coaxial Episcopic Illuminator

The integrated coaxial episcopic illuminator is ideal for illuminating surfaces uniformly, making it possible to measure every single detail on the surface, such as blind holes or writings and markings.

Up to 640 LED Annular Illuminator

Programmable up to 16 sectors. Arranged on two rings at different tilt angles, the annular illuminator lights up the part from any angle.

It is adjustable in height and can detect bevels or other elements on the surface.

Illuminator Sectors

One or more sectors of the annular illuminator may be selected independently, as well as the intensity of each individual sector.

Multi-touch Industrial Screen

Immediate Access: Multi-touch industrial 17-inch screen designed for clear visibility, and a user-friendly interface with intuitive programming to facilitate daily use.

Structure: Innovative construction techniques have resulted in a tool capable of operating outside the metrology lab. Its sturdy steel alloy frame with reinforcing ribs houses and protects the delicate parts of the machine.

Ergonomics: The loading area provides a great access space for the operator’s hands.

High Resolution:

Various versions available with a range of fields of view and resolutions. With just one picture METRIOS can capture even the most minute detail.

The software displays a high-resolution image of the entire element revealing the level of cleanliness and the presence of any burrs and scratches. The machine’s lens reduces distortion to a minimum at any point on the field of view, ensuring maximum accuracy.

Application

Metal Components Measurement Application | MEVIS Invests in Metrios technology

For over 50 years, Mevis has been the leading manufacturer of metal components on the international market. The company’s mission is clear: providing qualitatively superior and technologically excellent solutions, ahead of the times and needs of the market. For this purpose, the group constantly invests in developing pioneering solutions, focusing on and investing in

Download

Tiếng Việt

Tiếng Việt