MTP 170/170L

MTP 170 measuring range: 170×300 mm

MTP 170L measuring range: 170×380 mm

MTP is a machine designed to measure big-sized flat elements, offering maximum accuracy in quality control.

Its easy-to-use system and speed consent considerable reduction in terms of time and costs with accurate control and measurement of 100% of the production.

MTP is able to inspect multiple parts in one cycle, carrying out direct measurement and DXF profile comparison at the same time.

Overview

MTP effects measurement by means of a non-contact optical system. The system is made up of a linear camera and a telecentric back lighter, that effect vertical motions on the whole length of the piece.

The vision system creates a high-resolution image of the entire piece to be measured, that is then processed by means of powerful software analysis tools.

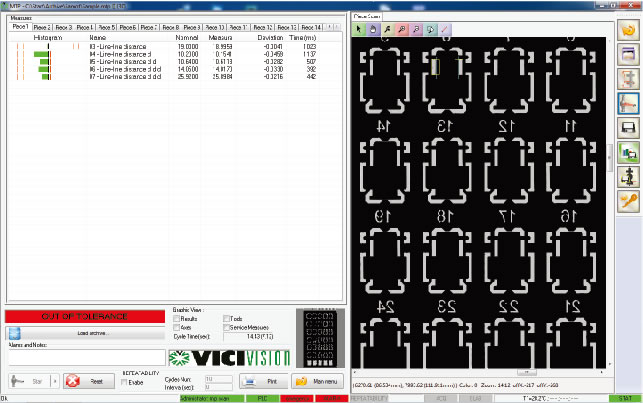

In the photo the machine is inspecting 35 lathed pieces in just 10 seconds. The speed of the machine combined with a rapid pallet change system makes it an unparalleled measuring device.

Video Product

Software

1. An intuitive graphic interface facilitates the operator’s task by detecting the pieces that have not passed inspection, as well as those out of tolerance.

2. Function of automatic recognition of the position and orientation of the pieces, for the automatic orientation of the measurement tools.

3. MTP automatically collects all the necessary data for statistical purposes and is capable of producing a report for every single piece measured.

4. Measurements: length, distance, angle, radii, linearity, symmetry, perpendicularity, parallelism, measures for perimeter, comparison of the profile detected with DXF.

Features

Frame

MTP consists of a strong aluminium frame made up of a fixed gantry and a movable table. The gantry, mounted directly on the mainframe of the machine with appropriate stiffening ribs, hosts the camera and the telecentric optics, in order to ensure no vibrations on the side of the camera.

Light Source

Under the camera, inside the mainframe of the machine, is located the light source with a telecentric optic to address the light beam directly to the camera.

Measuring Table

MTP is equipped with a horizontal movable table.

The stage is moved by a special belt system which ensures smooth movements and prevents the pieces from sliding during measurement.

In this way the operator can leave multiple parts on the table without the need to fix them with clamps or jigs.

The extractable stage provides easy access on three sides for an easy loading and unloading especially in case of multiple parts when operators are using both hands.

The measuring table performs a single and smooth movement along the Y direction. This ensures more stability in the shopfloor compared to machines with X-Y movements.

The measuring table exits completely from the protection area in order to offer a free access from the top extremely useful in case of automatic loading and unloading.

Application

Medical device application case | MTL measuring Ompi vial

Stevanato Group boasts more than 70 years of experience in the production of glass packaging. Ompi is a medical system division of Stevanaoto Group. It has branch companies in Italy, Slovakia, Mexico, China, Brazil and other countries. It provides a wide range of glass inner packaging materials, including the glass vials, a traditional product.

MTL Application | Interview with Italy Sarbo Minuterie Metalliche

Sarbo S.p.A. is a leading company in the specialized production of bar-turned small metal parts. The company is undergoing a crucial and advantageous period with a generational changeover from partners Luciano Zago and Giuseppe Sartor, to their children, Paolo Zago and Roberta Sartor. The new generation has enthusiastically welcomed the handing down of know-how and

Crankshaft Measurement | In Less Than A Minute

When it comes to quality control of such complex parts, measuring crankshafts can be a cumber some and time-consuming process, possibly requiring an environmentally controlled room. VICIVISION has developed a specific software tool dedicated to crankshaft measurements, able to provide dimensional control results of the highest accuracy. VICIVISION measurement systems offer a solution for specific

VICIVISION | Fittings and Turned Threads: How to Measure Them In A Few Seconds

Measuring Fittings, Turned Threads and Screws It is often difficult for manufacturers to get accurate and objective results when measuring turned threads, typical features on fittings and shafts, and rolled threads.By working closely alongside our clients and listening to their needs, we have developed a specific software for measuring fittings. In addition to standard

Download

Tiếng Việt

Tiếng Việt