White Light System

Precise Quality Control Via Optical Inspection

Single-point Compact Optical Sensor

The measurement of wafer in the field of semiconductor and generally microelectronics.

The measurement and online control of mechanical or optical parts.

The measurement and control of glass or plastic film thickness.

Overview

Our new sensor WLS performs non-contact distance and thickness measurements in proven accuracy. Thus, the device is perfectly customized for applications like determination of position and dimensions (e.g. for microelectronic components), topography, profile and roughness measurements (e.g. for tool surfaces) and thickness measurements of glass coatings.

The WLS offers great flexibility in a small space. The exceptionally compact control unit and the optical probes are connected by an optical fiber. This makes it possible to spatially separate the optical probe from the control unit. Furthermore, the probe does not contain any moving parts or electronic components that could influence the accuracy of the measurement as hear sources.

Thanks to its compact dimensions and economical price, the WLS is the ideal alternative to conventional laser triangulation sensors.

Specification

| VAS 500 | VIS 600 | VIS 4K | VIS 10K | |

| Measuring Range | 500 μm | 600 μm | 4 mm | 10 mm |

| Working Distance 1) | 12.7±0.5 mm | 6.5 mm | 37.5 ± 0.9 mm | 69 ± 1.7 mm |

| Thickness Measuring Range 2) | Up to 0.75 mm | Up to 900 μm | Up to 6 mm | Up to 15 mm |

| Axial Resolution | 20 nm | 3 nm | 180 nm | 400 nm |

| Linearity | 170 nm | 198 nm | 1.4 μm | 4 μm |

| Lateral Resolution | 2.5 μm | 2 μm | 4 μm | 16 μm |

| Measuring Angle to the Surface 3) | 90°±45° | 90°±30° | 90°± 20° | 90°± 14° |

| Weight | 250 g | 71 g | 162 g | 209 g |

Remarks:

1) Bottom of optical probe to middle of measuring range.

2) Refractive index n = 1.5 on transparent material.

3) Decreasing accuracy for large incident angles.

The given data was generated for a typical application and may be different given other circumstances.

Features

EFFICIENT

Cost-efficient solution

State-of-the-art chromatic confocal technology

Measurement on all surfaces

No shadowing due to coaxial measurement

VERSATILE

Simple to integrate

Optical probe and controller are separate

Maintenance free and robust

Small footprint

USER-FRIENDLY & SAFE

Insensitive to heat and pollution

Light weight

Low power consumption

Application

Measurement Production Line Upgrade | Robot Automatic Loading and Unloading

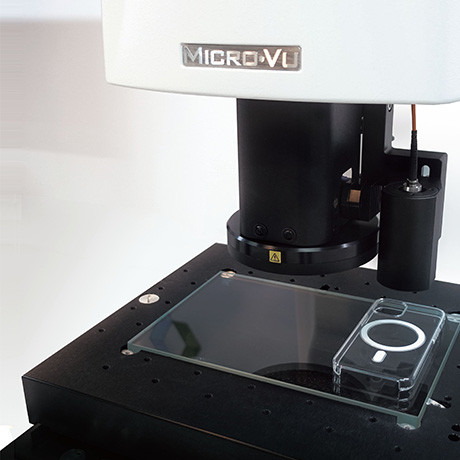

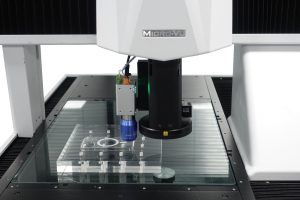

Knotless Screen Mapping Application | Micro-Vu High Precision Vision Measuring Machine

Cell Measurement Application | Micro-Vu high-precision vision measuring machine

Download

Tiếng Việt

Tiếng Việt